Product

Vertical Moulding Machine

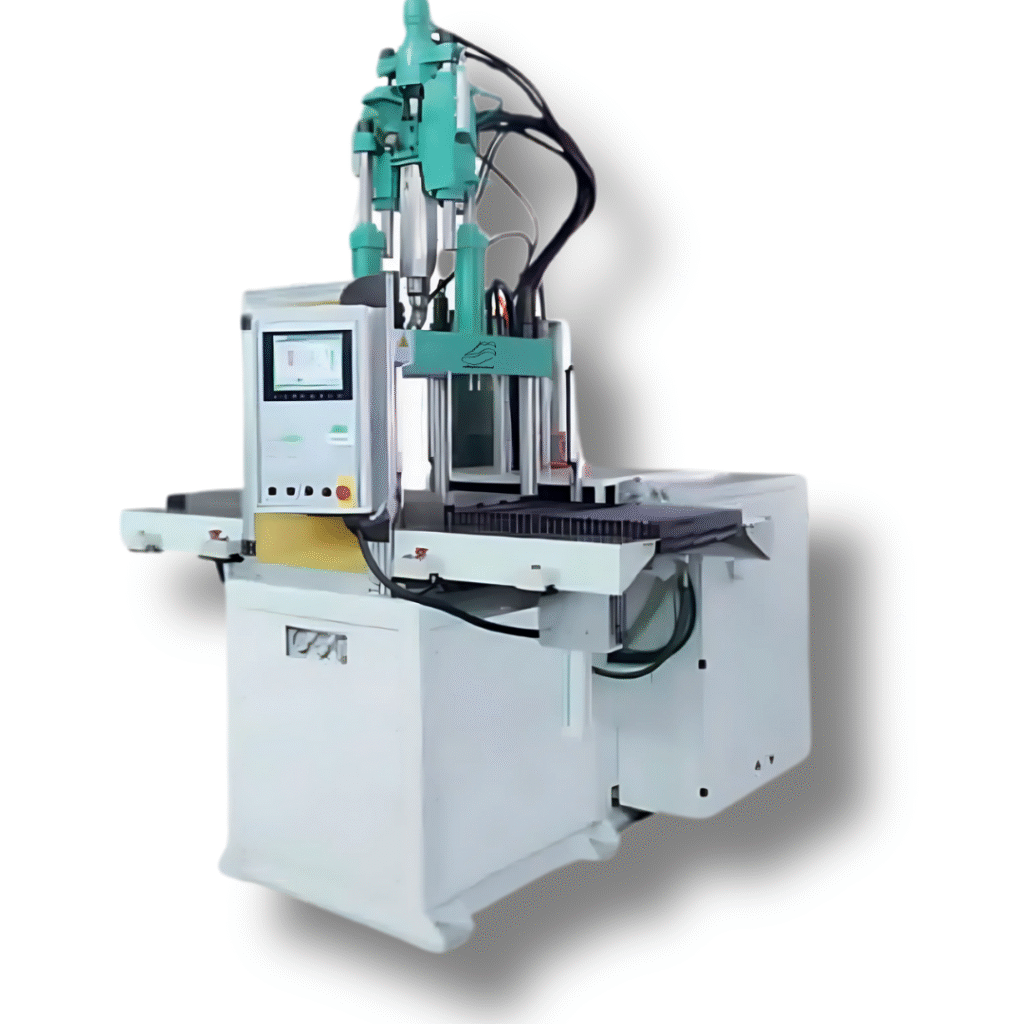

NVF Standard Series

Vertical clamping & with fixed table for easy insert moulding and product removal.

Multi-stage temperature control for stable, high-quality production.

Hydraulic direct-pressure mould locking ensures quick, steady, and mould-protective clamping.

Fixed table with ejector device for easy insert positioning and faster product removal.

Uses globally trusted components for precise, durable, and low-noise performance.

Customizable hydraulic options: manual, single ratio, double ratio, or servo system.

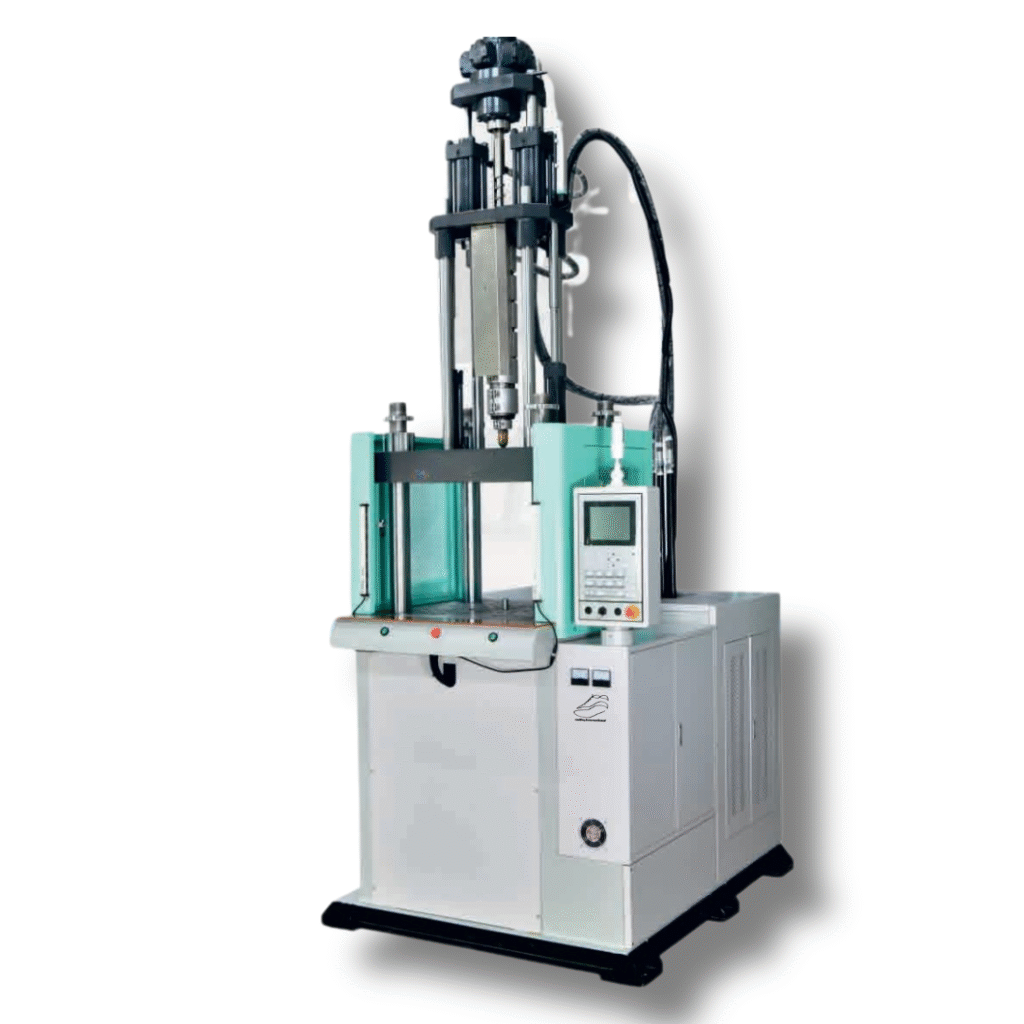

NVR Rotary Table Series

- Rotary working table design for easy product insertion and removal, enhancing safety and production efficiency.

- High-precision positioning system ensures accurate mould alignment for consistent quality.

- Compatible with automatic inserting and take-out systems for fully automated operation.

- Standard 2-station configuration, with optional 3 or 4-station designs available.

NV - 1S Single Slide Table Series

Single slide table design moves the lower mould forward after opening for improved safety and operator convenience.

Multi-stage temperature control for precise speed and back pressure adjustment, ensuring stable product quality.

Expandable control system compatible with embedded and automation equipment for fully automatic production.

NV - 2S

Single slide table (NV-T-2S series) with one upper mould and two lower moulds — enabling one mould while the other is loaded, boosting production by 30–50%.

Vertical and clamping with four-column design for easy and precise insert moulding.

Flexible hydraulic system options (semi-closed, fully closed, servo, or high-speed) to suit various production needs, with expandable programs for full automation.

Adjustable ejector system allows easy setting of slide table stroke, demoulding force, speed, and cycle times for different production requirements.